I picked up this older briefcase at auction in 2018. It was a good deal. Listed as locked, no knowledge of the contents at the time, and sold for way less than a used case of this variety would normally sell for. I like these cases. Each half of the shell has small bracket tabs which can be used to install aluminum panels, making them ideal for portable radio or other instrumentation installs. I was confident I’d be able to get into it one way or another.

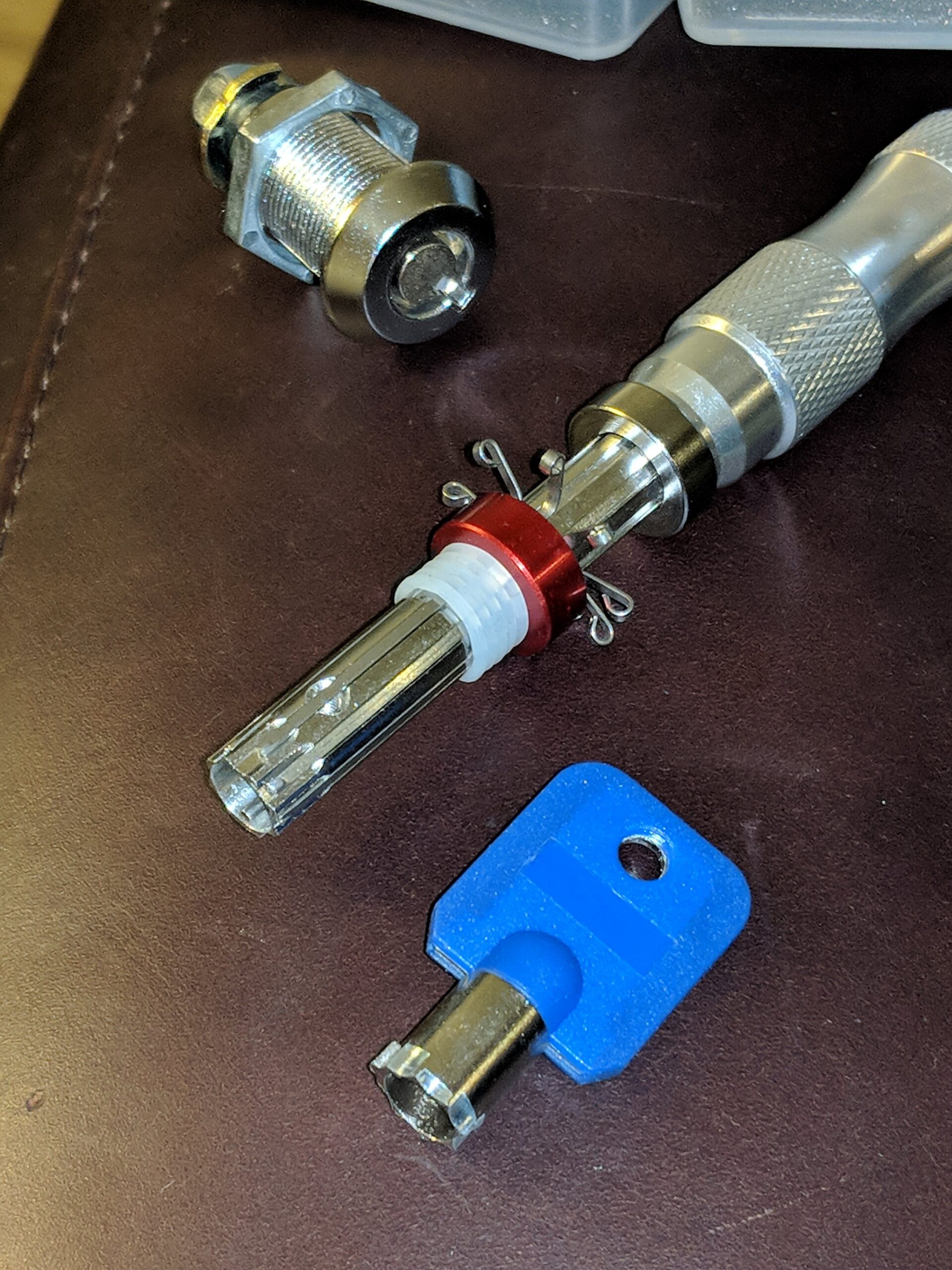

Indeed, I was able to get in by popping the hinge pin. From there I was able to remove the lock mechanism from the inside. It’s not a sophisticated protection mechanism, nor is it a particularly secure case. I’m going to venture to guess the new ones are even less secure, since they have TSA locks.

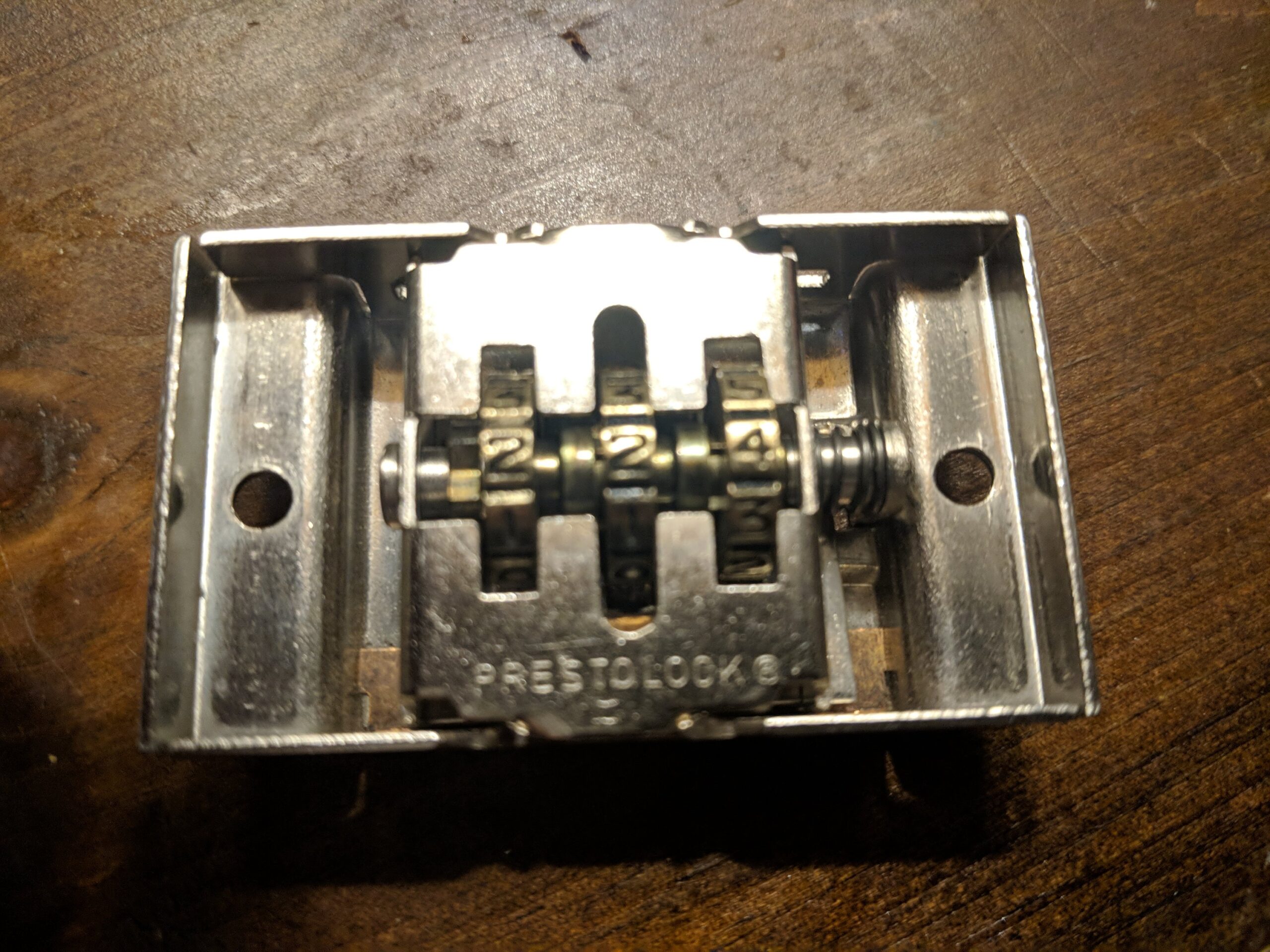

I spent quite a bit of time (before popping the hinge pin) brute-forcing the lock. You’d think that with only three 0-9 dials, just 1,000 possible combinations, that that would be sufficient, but I found that even with several tries, before and after removing the lock mechanism from the case, I was unable to make it happen. I think it’s a matter of imperfections in repetitive motions. After a certain amount of times, I guess your hands just “expect” the movement to continue to fail, and you fail to follow through with enough strength to clear the mechanism even when you get the right combo.

Last night I decided to give it another go.

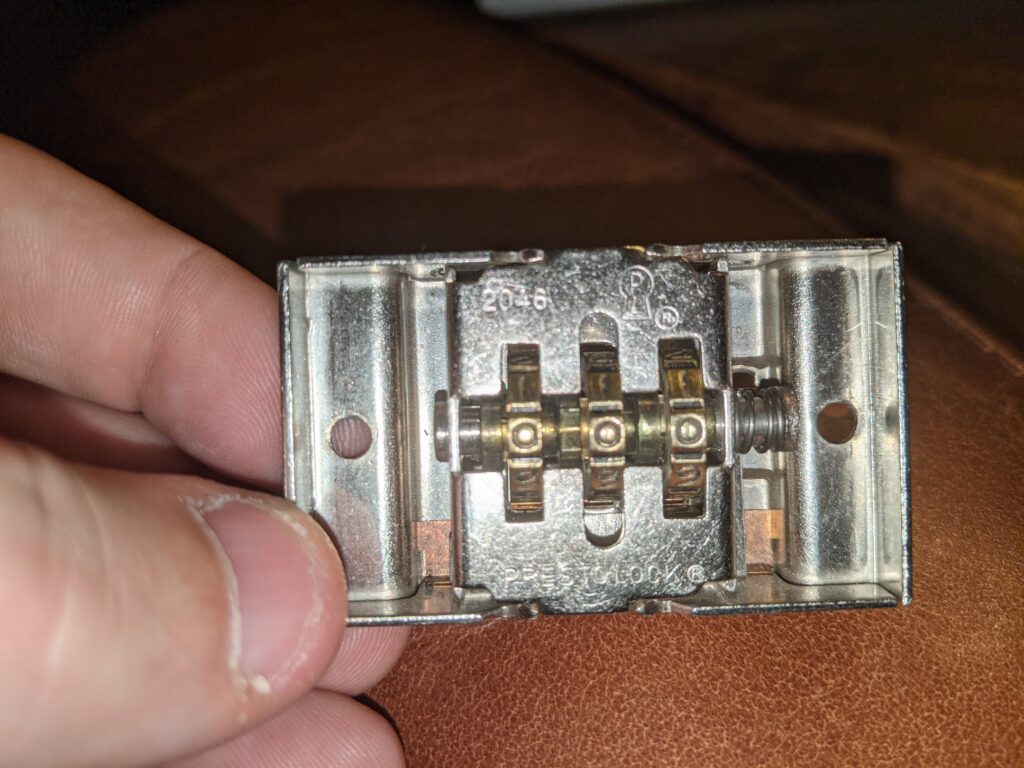

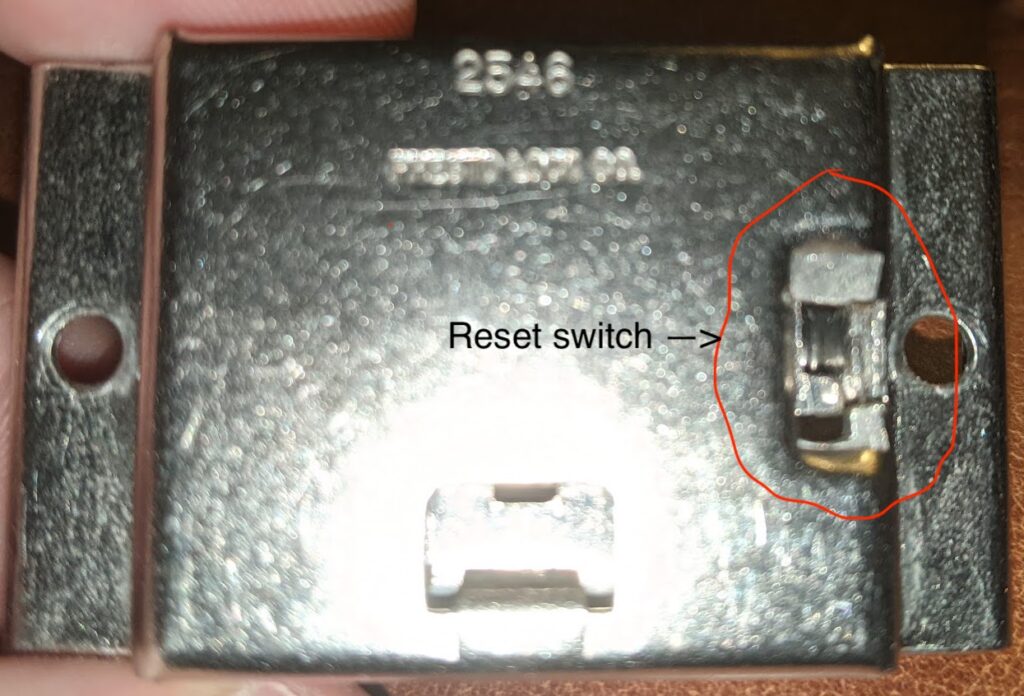

When brute-forcing with the lock attached, the test is to attempt to open the case. When brute-forcing with the lock removed, the test is to attempt to slide the combination-reset switch on the back of the mechanism, which won’t budge without the right combo. Again, repetitive motion attention failure likely prevented this from working properly, so I went back to the drawing board and researched bypass techniques with wheel-based combination locks such as this one. I found one technique involving proving to the right of the wheel with a narrow probe while turning the wheel and feeling for a “notch.” I tried that, and lo and behold, I found that each wheel had a notch point, in my case corresponding to “7-5-8.” I engaged the reset switch, and it worked!

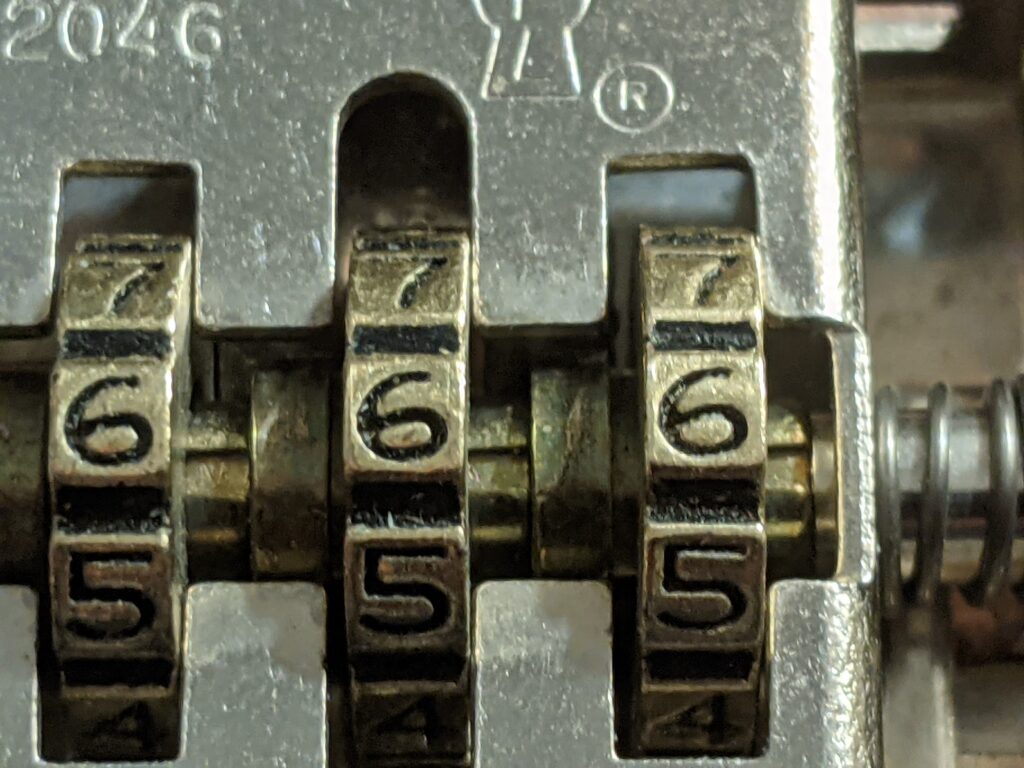

The reset switch is engaged by sliding it inwards, then upwards. It can only be engaged while the correct combo is set, and while engaged, any changes to the dials result in a change of the combination. I reset the combo to 666, just so it’s easy to remember for now, and reinstalled it in the case. Tests showed that the new combo works, and the case is both lockable and unlockable.

Here’s a photo of what the notches look like without the front cover. Interestingly, this mechanism, a Prestolock 2046 or 2546, is installed by screwing the lock mechanism directly to receiver tubes on the front cover from the inside. With the lock installed, you can’t see these notches. But knowing they’re there, on this and lots of other wheel-based combo locks, will help you to easily determine the current combination and disengage the lock. If your lockpicks are thin enough, they may work for feeling these notches even with the front cover engaged.