The world of amateur consumer-grade 3D printing is fraught with challenges and opportunities for catastrophic failure.

We were on a pretty good roll for a while, some good large pieces completed nicely, we got the bed leveling procedure down to a science, the system seemed pretty reliable. Unfortunately, purely mechanical systems like this (at its core, 3d printing is just motors and heaters) prefer to revert to chaos. Vibration shakes things loose, and then all bets are off.

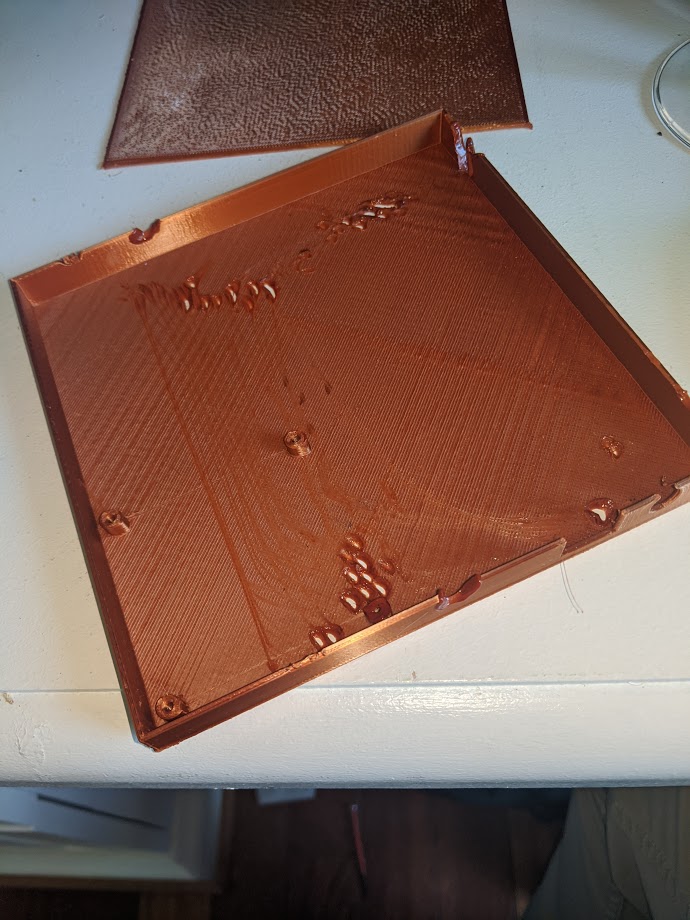

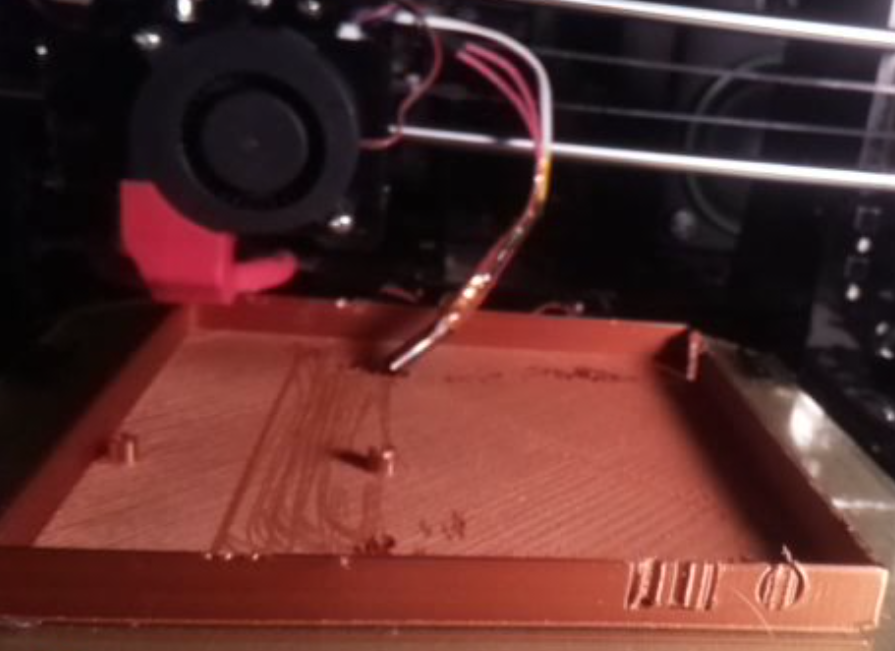

In this case, this piece was probably 80% done when the heating element set screw vibrated loose, and then the heating element itself shook itself loose from the extruder block, and then was just dragged around on the bed by its wires until it was discovered about 15 minutes later. You can see the melted areas along the rim where it dragged over those edges repeatedly, and then the melty paths along the floor of the surface where it was simply dragged across the floor. Gorgeous, and not the quickest repair job for the printer either.